How to Clean a Rusty Knife: A Comprehensive Guide

Posted by BladeOps on Feb 5th 2024

Smith & Wesson OTF Knives

Posted by CT on Feb 5th 2024

Switchblade Maintenance and Care: How to properly maintain and care for a switchblade to ensure longevity

Posted by CT on Jan 15th 2024

The History of Folding Knives: From Ancient Times to the Present

Posted by CT on Jan 12th 2024

An Overview of Military Grade Automatic Knives

Posted by CT on Jan 9th 2024

Unveiling the World of High-Quality Knives: Spyderco vs Benchmade

Posted by BladeOps on Dec 20th 2023

Five Best Selling OTF Knives of 2023

Posted by CT on Dec 7th 2023

A History of the Automatic Knife: From Military to Everyday Use

Posted by PT on Nov 30th 2023

A Comprehensive Guide: What is an OTF Knife?

Posted by BladeOps on Nov 27th 2023

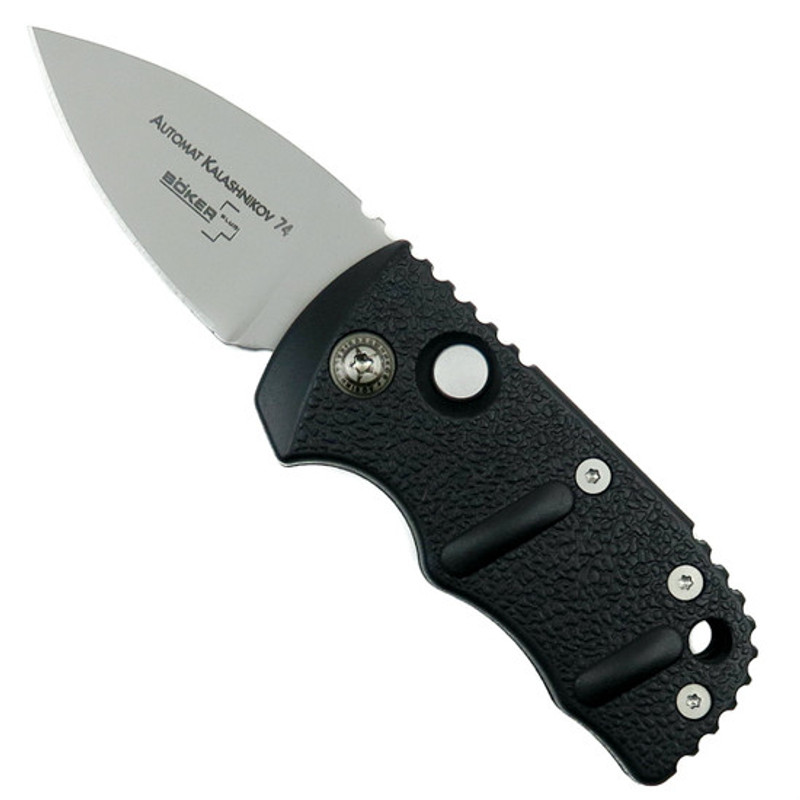

Are Boker Knives Good Quality Knives?

Posted by BladeOps on Nov 6th 2023

What Are Serrated Knives Used For?

Posted by BladeOps on Sep 18th 2023

First Thoughts Knife Review: CRKT P.S.D. II Knife

Posted by PT on Aug 23rd 2023

First Thoughts Knife Review: CRKT Bot Knife

Posted by PT on Aug 22nd 2023

Knife Review: Microtech Bounty Hunter Combat Troodon

Posted by PT on Aug 22nd 2023

TOPS Knives: Knives With Purpose

Posted by PT on Aug 21st 2023